Brand/Jenama : Proton

Model : Saga

Year/Tahun : 1989

Color : Grey/Brown

Engine & Performance/Enjin & Kuasa

Model : 4G15 Magma 8v

Converted to : 4g15 12v injection

Modification/Modifikasi

Injection 1.5 MMC

Head 12v injection with port and polish + custom regrind camshaft tuned by NSM Auto

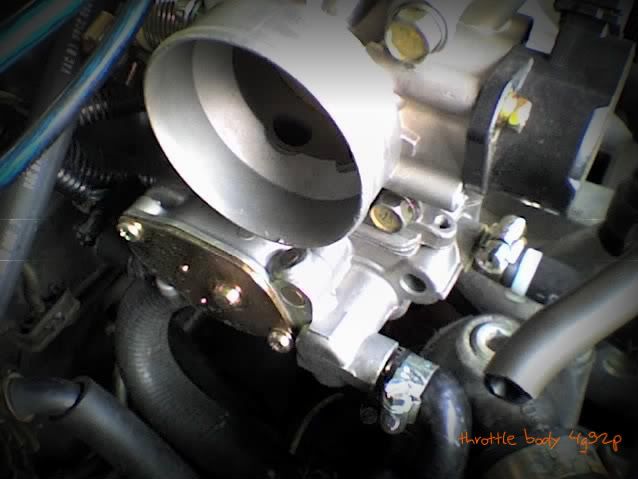

4g92p 1.6sohc throttle body (54mm)

Arospeed Adjustable campulley

Bosch external fuel pump

Simota Air Filter

FICD Toyota - control aircond

Full 1.8 piping + 4-2-1 Zenden Bling ! Bling ! Extractor and Bullet

Perendam bunyi HKS SuperDragger

Plug Cable NGK Blue

Palam Pencucuh NGK Platinum

Grounding Cable + voltage stabilizer

ns70 Free Maintainance Battery with bigger alternator

Exedy Clutch set + lighten flywheel

Starter Hybrid Honda Perdana VR4

power steering.

Interior/Dalaman

Standard Saga

Steering Momo 3kaki

Turbo Timer (poyo2 je)

Sepasang Bucket Seat Replika Sparco

Volt and Vacuum meter dr Autogauge

Exterior/Luaran

Side Skirt vr4 + lips supertouring

Standard Saga Magma 1989

Tinted Silver Dust

spoiler E30 kecik

Grill sodok Gabanz c12 (thanks uncle gemposs)

Suspension System/Sistem Gantungan

Depan - customade absorber ( potong tread kasi rendah + tkr minyak dalam kasi lg keras) + sport spring APM

Belakang - Kayaba + perdana Honda SV4 ( potong 1 lingkar )

Braking System/Sistem Brek

Master pump dan servo Mitsubishi Lancer

Disc depan VR4

Disc belakang VR4

Rolling Wheel/Rim & Tayar

K-Speed ( Klon TE37 ) 15'

Silverstone Kruizer 195/50/15

ICE

CD/CDR/CDRW/MP3 Playable Player+ speaker Pioneer + tweeter ICE STEREO

SagaBuruk2889 Future Upgrade

*

*

*

*

* Greddy E-manage

* Injector 1.6 182cc

* 1.6 Stroker Kit

* Exedy Racing Clutch Set

* New Tyre

* New Paint

Sedikit Gambar....